Auto body moldings are essential components that enhance both the appearance and structural integrity of modern vehicles. While their custom designs improve aesthetics, they also facilitate efficient collision repair by offering quick replacement solutions for damaged areas. Despite challenges posed by varying vehicle models and manufacturing tolerances, advanced engineering and precise manufacturing techniques ensure perfect alignment. Innovation in auto body molding technologies, driven by precision and customization demands, has led to the use of 3D scans and advanced fabrication methods like laser cutting and robotics. These advancements have revolutionized car body restoration, achieving flawless aesthetic and structural outcomes after accidents.

Auto body moldings, those elegant trim pieces that enhance a vehicle’s aesthetic, play a crucial role in protecting its exterior while adding a touch of style. This article delves into the world of precise auto body moldings, exploring their significance and how they transform the automotive industry. We examine the challenge of achieving universal fit across diverse vehicle models and highlight innovative technologies overcoming these manufacturing differences. Get ready to discover the art and science behind custom-fit auto body moldings that elevate every ride.

- Understanding Auto Body Moldings: Their Role and Benefits

- The Challenge of Universal Fit: Overcoming Manufacturing Differences Across Vehicle Models

- Innovative Technologies and Techniques for Creating Custom-Fit Auto Body Moldings

Understanding Auto Body Moldings: Their Role and Benefits

Auto body moldings play a pivotal role in the automotive industry, offering both aesthetic and functional advantages. These intricate pieces are designed to precisely fit various vehicle models, enhancing the car’s overall appearance and protecting its exterior from damage. By seamlessly integrating with the vehicle’s design, auto body moldings create a sleek and uniform look, adding value and appeal to the car.

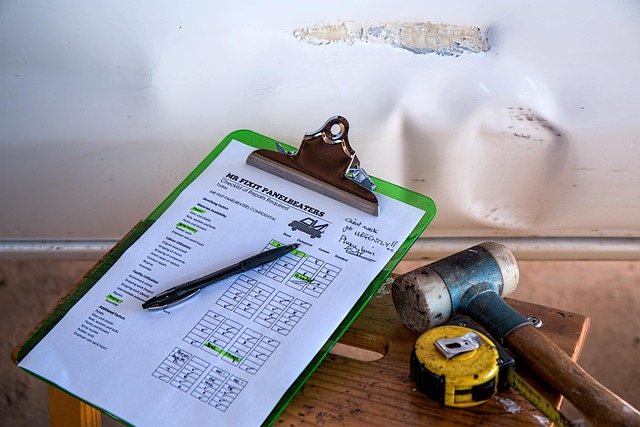

Beyond aesthetics, they serve a crucial function in collision repair and automotive bodywork. In the event of an accident or damage, these moldings help in quick and precise repairs, ensuring that the vehicle returns to its original state. Their versatility allows for easy replacement, making them indispensable in the field of auto body repair and maintaining the integrity of modern vehicles.

The Challenge of Universal Fit: Overcoming Manufacturing Differences Across Vehicle Models

Creating auto body moldings that fit precisely on every vehicle model presents a unique challenge. Each car manufacturer has specific design nuances and manufacturing tolerances, making it difficult to create universal parts that cater to all. The diversity in vehicle models, from sleek sedans to robust SUVs, further complicates matters.

Overcoming these differences requires advanced engineering and precise manufacturing processes. Experts in auto body restoration and vehicle paint repair employ sophisticated techniques to ensure the moldings align perfectly with each car’s unique contours. This involves meticulous attention to detail, from measuring frame dimensions to replicating intricate design elements, ultimately resulting in seamless integration of the auto body moldings onto any vehicle model.

Innovative Technologies and Techniques for Creating Custom-Fit Auto Body Moldings

The automotive industry’s relentless pursuit of precision and customization has led to innovative technologies and techniques for crafting auto body moldings that perfectly fit various vehicle models. Gone are the days when standard, one-size-fits-all parts were the norm. Today, advanced engineering and computer-aided design (CAD) systems enable manufacturers to create custom molds based on detailed 3D scans of specific car models. This ensures that every curve, contour, and crevice is replicated with remarkable accuracy.

Moreover, the integration of laser cutting and robotic fabrication has revolutionized auto body molding production. These technologies allow for intricate designs and precise cuts, enabling the creation of complex panels that seamlessly integrate into a vehicle’s existing structure. As a result, car body restoration and automotive collision repair processes have become more efficient and effective, ensuring vehicles return to their pre-accident condition with flawless aesthetics and structural integrity.

Auto body moldings play a pivotal role in vehicle aesthetics and protection. The challenge of achieving universal fit across diverse vehicle models has been met through innovative technologies and techniques. By overcoming manufacturing differences, these custom-fit moldings ensure precise alignment and enhanced structural integrity. This advancement not only improves the overall look but also boosts vehicle safety, proving that auto body moldings are an essential component for every vehicle owner.